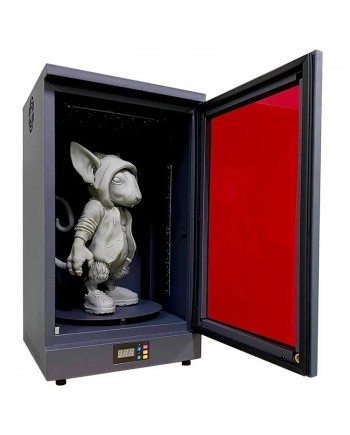

Phrozen Cure Mega S: Professional Post-Curing Station for Large Resin 3D Prints

Quick Features Overview

- Dual high-speed fans operating at 1700 RPM for maximum drying efficiency

- 360-degree transparent rotating turntable for even curing coverage

- Large curing chamber accommodating prints up to 350mm diameter and 300mm height

- Flexible dry and cure settings for consecutive processing

- Built-in interior lighting for real-time monitoring

- Detachable rack system for flexible model arrangement

- 405nm UV LED technology with adjustable curing cycles

- Universal compatibility with LCD, DLP, and SLA resin 3D printers

Professional-Grade Curing Performance

Advanced Dual-Fan Drying System

The Cure Mega S features a dual high-speed fan system engineered specifically for resin 3D printing workflows. Each fan operates at 1700 rotations per minute, delivering exceptional air circulation that removes excess resin and solvents from printed models in minutes rather than hours. This powerful drying capability is particularly valuable for batch processing, where multiple models need rapid turnaround between curing cycles. The dual-fan design ensures consistent airflow throughout the curing chamber, preventing damp spots and incomplete drying that could compromise print quality.

360-Degree Transparent Turntable Technology

The rotating turntable platform provides complete 360-degree coverage, ensuring uniform UV exposure from all angles. Models rotate continuously during the curing process, eliminating shadowed areas and guaranteeing even light penetration. The transparent construction allows you to monitor your models throughout the curing cycle without opening the chamber. This feature is essential for achieving consistent surface finish and mechanical properties, especially when curing large or complex geometries that require thorough UV saturation.

Versatile Dry and Cure Settings

This curing station offers flexible operational modes that adapt to your specific workflow. You can select dedicated drying cycles, dedicated curing cycles, or combine both processes consecutively for comprehensive model treatment. The adjustable curing timer ranges from 1 to 120 minutes, with Phrozen recommending a maximum of 30 minutes per cycle for optimal results. This versatility makes the Cure Mega S suitable for different resin types, print sizes, and production requirements, from small precision components to large display pieces and functional prototypes.

Built-In Interior Illumination

The integrated interior light provides clear visibility of your models during drying and curing operations. This convenient feature eliminates guesswork about curing progress and allows you to assess print quality without opening the chamber door. Real-time visibility helps you make adjustments and ensures you can observe any issues with surface finish, cure uniformity, or material behavior as they occur.

Expandable Curing Capacity

Large Curing Chamber Dimensions

With a maximum curing capacity of 350mm diameter by 300mm height, the Cure Mega S accommodates large individual prints or multiple smaller models simultaneously. The spacious chamber design eliminates the need to cure parts separately, significantly improving production efficiency. Whether you're working with large functional prototypes, artistic sculptures, or production batches of smaller components, this capacity ensures flexibility for diverse project requirements.

Detachable Rack System

The included detachable rack provides adjustable positioning options to maximize chamber space utilization. You can remove the rack for single large models or use it to organize multiple smaller prints vertically. This modular approach lets you customize the curing arrangement based on your specific needs, improving batch processing efficiency and accommodating varying model sizes without additional accessories.

Technical Specifications

| Specification |

Value |

| Machine Dimensions |

Length: 39.5 cm | Width: 47.5 cm | Height: 48.6 cm |

| Maximum Curing Size |

Diameter: 350mm (Ø35) | Height: 300mm |

| UV Light Wavelength |

405 nanometers (nm) |

| Dual Fan Speed |

1700 rotations per minute (RPM) |

| Curing Time Range |

1 to 120 minutes (Recommended: Maximum 30 minutes per cycle) |

| Input Voltage |

AC 100-240V | 50/60 Hz |

| Machine Weight |

15 kilograms (kg) |

| Maximum Power Consumption |

70 watts (W) |

| Turntable |

360-degree rotating transparent platform with removable rack |

| Compatibility |

LCD, DLP, and SLA resin 3D printers |

Ideal Applications and Use Cases

High-Volume Production Environments

The Cure Mega S excels in professional production settings where consistent throughput is essential. The large chamber combined with dual high-speed fans enables rapid processing of multiple models per hour. Whether you're running a dental lab, jewelry production facility, or manufacturing operation, this curing station maintains the workflow momentum necessary for commercial success while ensuring superior post-processing quality.

Dental and Medical Device Manufacturing

Precision is paramount in dental and medical applications. The uniform 360-degree curing ensures consistent material properties and dimensional accuracy across every produced part. The extended curing capacity allows processing of multiple dental models, surgical guides, or medical components in single cycles, improving laboratory efficiency without compromising quality standards.

Jewelry and Fine Art Production

Artisans and jewelry makers benefit from the transparent design and even curing performance. The ability to cure intricate designs and fine details uniformly ensures superior surface finishes and accurate color reproduction. The large capacity accommodates both individual statement pieces and production batches of smaller components like earrings, rings, and pendants.

Engineering and Prototyping Services

Product development teams rely on the Cure Mega S for consistent prototype quality throughout iterative design cycles. The flexible curing settings accommodate different resin types and thicknesses, essential for validating designs across various material specifications. Fast curing times accelerate the design iteration process, enabling rapid testing and refinement.

Batch Curing and Production Scaling

As your 3D printing volume grows, the Cure Mega S scales with your business. Process multiple production batches without sacrificing individual part quality. The energy-efficient 70-watt operation keeps running costs minimal even during extended production sessions.

Product Features Detailed Overview

Premium 405nm UV LED Technology

The 405-nanometer ultraviolet wavelength is specifically optimized for most commercially available photopolymer resins. This wavelength provides the ideal energy level for cross-linking polymer chains without excessive heat generation that could warp or damage prints. The wavelength choice represents decades of resin formulation optimization across the 3D printing industry.

Energy-Efficient Operation

With a maximum power consumption of just 70 watts, the Cure Mega S offers exceptional efficiency compared to older halogen or mercury vapor curing systems. The LED technology generates minimal heat while delivering powerful UV output, creating a safer work environment and reducing operational costs. The universal input voltage (100-240V, 50/60Hz) makes this station compatible with global power standards.

Robust Industrial-Grade Construction

The 15-kilogram machine features a solid build designed for continuous professional use. The acrylic chamber door provides optical clarity while protecting the interior environment and ensuring operator safety. The transparent turntable rotates smoothly on precision bearings, maintaining alignment and performance through thousands of curing cycles.

Smart Temperature Management

Dual high-speed fans maintain optimal chamber conditions by removing heat generated during UV curing and helping evaporate residual cleaning solvents. This active thermal management prevents excessive temperature buildup that could affect resin properties or create uncomfortable working conditions. The system maintains optimal curing parameters even during extended production runs.

Why Choose the Phrozen Cure Mega S for Your 3D Printing Workflow?

Professional Results Consistency

Every print receives uniform curing treatment through the combination of 360-degree rotation and consistent UV exposure. This delivers predictable mechanical properties, dimensional accuracy, and surface finish quality across all produced parts. Professional standards require this level of consistency, and the Cure Mega S delivers it reliably.

Production Efficiency and Throughput

The large chamber capacity and rapid drying capabilities translate directly to increased productivity. Process more models per hour, reduce turnaround times, and meet client deadlines more effectively. The flexible dry and cure modes let you optimize your specific workflow rather than adapting to equipment limitations.

Long-Term Value and Reliability

Phrozen's commitment to quality ensures this equipment remains productive for years of continuous operation. The one-year warranty on the curing station demonstrates manufacturer confidence in durability and performance. LED technology eliminates the bulb replacement costs associated with older curing methods, further improving total cost of ownership.

Seamless Integration with Phrozen Printers

The Cure Mega S complements Phrozen's entire printer lineup including Sonic, Sonic Mini, and Sonic Mega series. Phrozen designs their equipment ecosystem to work together seamlessly, ensuring optimal results when using genuine Phrozen resins and complementary equipment.

Safety and Maintenance Considerations

Essential Safety Precautions

Always disconnect the power cable before performing maintenance or cleaning. Never open the acrylic door while the machine is operating, as exposure to active UV light can cause eye damage. Maintain proper ventilation in your work area, and avoid direct skin contact with uncured resin and cleaning solvents. In case of contact with uncured resin or isopropyl alcohol, rinse immediately with plenty of water and seek medical attention if symptoms persist.

Routine Maintenance

The durable construction requires minimal maintenance. Periodically wipe the interior chamber with a soft, lint-free cloth to remove dust. Check the turntable rotation and ensure the acrylic door seals properly. The LED system requires no bulb replacement, eliminating a major maintenance task associated with traditional curing equipment.

Frequently Asked Questions About the Cure Mega S

What resin types work with the Cure Mega S?

The 405nm wavelength is compatible with the vast majority of commercial photopolymer resins including standard resins, engineering resins, dental resins, and jewelry resins. Check your specific resin manufacturer's recommendations to confirm compatibility, though most commonly available resins work excellently with this wavelength.

How long does it take to cure a typical print?

Curing time varies based on print size, thickness, and resin type. Most prints complete curing within 5 to 30 minutes. The adjustable timer ranges from 1 to 120 minutes, allowing precise control. Phrozen recommends a maximum of 30 minutes per cycle for optimal results.

Can I cure multiple prints simultaneously?

Yes, the large 350mm diameter chamber accommodates multiple smaller prints arranged using the detachable rack system. The 360-degree rotation ensures even coverage even with multiple models. This multi-model capability significantly improves production efficiency for batch processing.

Is the Cure Mega S suitable for commercial production?

Absolutely. The robust construction, energy efficiency, and consistent performance make this station ideal for professional laboratories, manufacturing operations, and production-oriented businesses. The large capacity and dual-fan system support continuous operation necessary for commercial environments.

What's the difference between dry and cure modes?

Dry mode uses the fans to remove excess resin and solvents from print surfaces. Cure mode activates the UV lights to cross-link the polymer and harden the resin. Combined mode runs drying followed by curing in a single cycle. The flexibility to separate or combine these processes lets you optimize your specific workflow.

Does the Cure Mega S require special ventilation?

While the LED technology generates minimal emissions compared to traditional curing methods, adequate workspace ventilation is recommended to manage any residual volatile organic compounds from cleaning solvents. Standard workshop ventilation is typically sufficient.

What's included in the package?

The Cure Mega S ships with the main curing chamber, the 360-degree transparent turntable, a detachable rack system, and necessary power cabling. Additional accessories are available separately if needed for specific applications.

What warranty coverage applies?

Phrozen provides a comprehensive one-year warranty covering all components except consumables such as LCD screens (3-month coverage for certain printer models) and FEP film. Extended warranty options may be available through authorized distributors.

Customer Testimonials and Professional Use

The Cure Mega S has earned recognition among dental labs, jewelry makers, and manufacturing professionals who demand consistent, reliable post-processing. Its combination of large capacity, rapid processing speed, and uniform curing results has made it a favorite among users who require commercial-grade equipment without excessive complexity or maintenance requirements.

+

+ +

+ +

+ +

+