Why Advanced Engineering is Transforming DIY and Industrial 3D Printing

Why Advanced Engineering Is Transforming DIY and Industrial 3D Printing

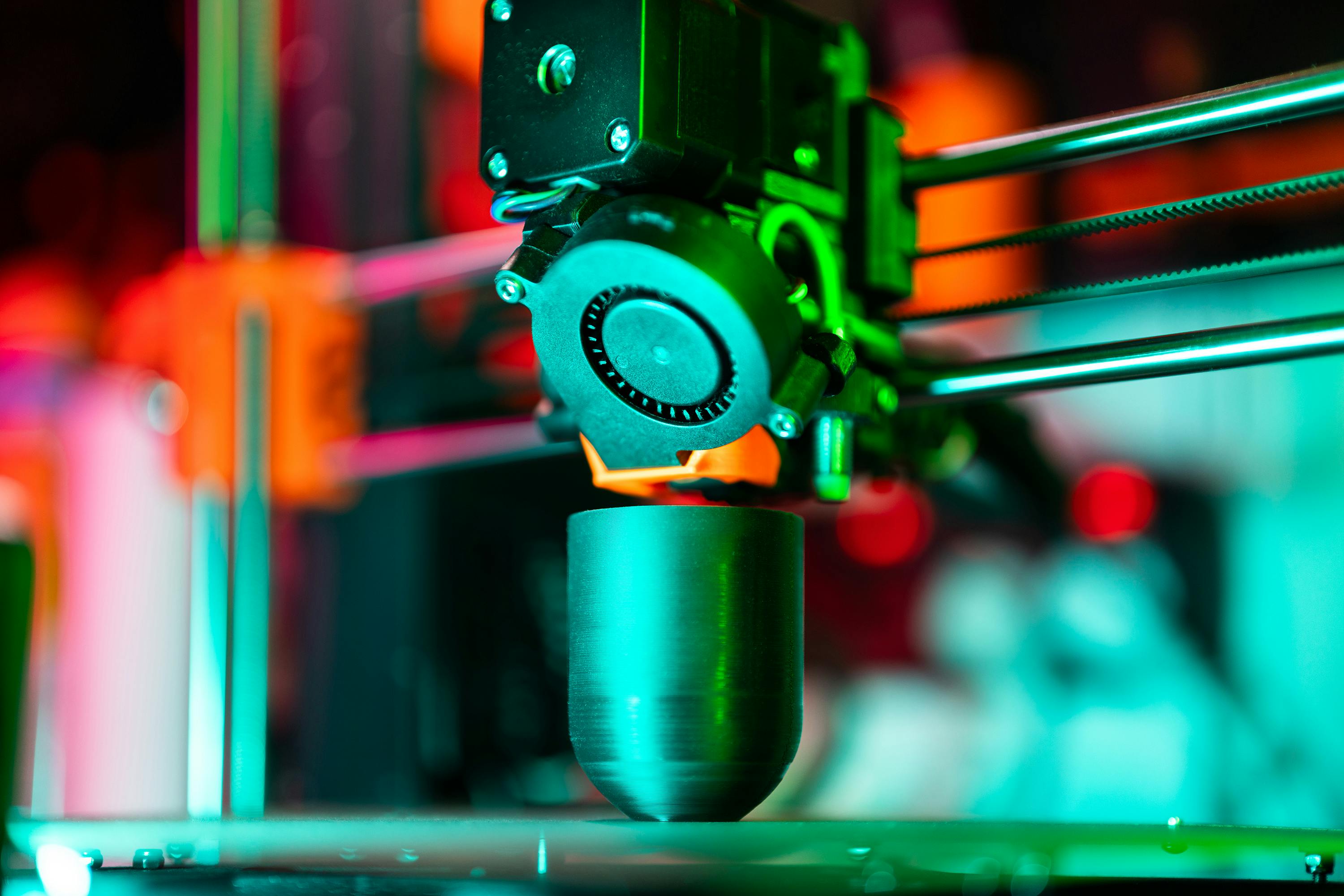

The global 3D printing market is expected to top $100 billion by 2032, driven by an explosion of new materials, smarter machines, and faster design cycles. What started as a tool for hobbyists tinkering in garages has evolved into a critical force in aerospace, medicine, and manufacturing.

Yet, what’s powering this leap isn’t luck or hype — it’s engineering. From precision motion systems to heat-resistant polymers, the science behind these machines keeps getting sharper. Today, the same principles that guide industrial engineers are shaping how makers experiment at home. Advanced engineering isn’t just improving 3D printing — it’s transforming what’s possible for everyone using it.

The Engineering Behind Modern 3D Printing

Modern printers are far more than clever gadgets. They’re precision-built machines that merge mechanics, electronics, and software into one system. Understanding how they’re engineered gives you a sense of why today’s 3D printing feels so effortless — and so powerful.

Precision Mechanics and Design Tolerances

Every print depends on movement accuracy. Engineering advances make that possible. Stiffer frames, quieter stepper motors, and better linear rails help printers hit tight tolerances without vibration or wobble. Even small tweaks, like improved cooling or refined extrusion paths, make a visible difference in print quality.

Behind every steady print lies smart design. The control boards that manage heat, motion, and power need to be just as precise as the mechanics. Many builders source their boards from companies like WellPCB, which specialize in reliable PCB manufacturing for custom and commercial setups. That attention to detail keeps printers running smoothly, even on long jobs.

Smarter Materials and Performance Innovation

Hardware sets the foundation, but materials drive the possibilities. New composites, high-temp polymers, and flexible resins have replaced the brittle plastics of the past. It’s now common to see home printers turning out drone frames, car parts, or functional prototypes once limited to factories.

These materials don’t just survive higher stress — they thrive under it. Thanks to better chemistry and smarter additives, filaments now resist warping, deliver cleaner finishes, and last longer. Engineering has turned “plastic printing” into genuine manufacturing.

From DIY to Industrial — Closing the Gap

A few years ago, home and industrial 3D printing felt like separate worlds. That gap keeps shrinking. The same open-source principles that built the maker movement are now shaping how professionals approach production.

Pro-Level Tools for Makers

Not long ago, only big manufacturers had access to precision control and advanced firmware. Now, mid-range desktop printers include many of the same features — automatic bed leveling, multi-material printing, and temperature-tuned extruders. Makers can fine-tune their machines with the same precision engineers use in professional labs.

This shift is more than technical. It’s cultural. Engineering knowledge that once lived behind closed factory doors is now shared openly, inspiring a generation of DIY inventors to experiment and build.

Shared Engineering Communities

The internet has become the world’s biggest engineering lab. Makers swap CAD files, firmware upgrades, and print profiles daily. Someone in Germany might design a new nozzle system, while a small shop in Mexico tests and improves it the same week.

This constant exchange fuels innovation at every level. Collaboration, not competition, drives most of the progress. What used to take months of research now happens in days, thanks to thousands of problem-solvers working together.

The Role of Electronics in Print Precision

If mechanics give a printer its body, electronics give it a brain. Sensors, controllers, and drivers all work in sync to manage temperature, motion, and flow — keeping prints accurate and consistent from start to finish.

The printed circuit board (PCB) is the heart of that system. Multi-layer board designs prevent electrical noise, regulate heat, and synchronize motor control. Without that foundation, even the best mechanical design would fall short. As printers evolve with more automation and sensors, precise PCB engineering becomes even more critical.

The connection between hardware and electronics defines the reliability of a modern 3D printer. It’s the difference between something that simply prints and something that performs.

How Advanced Engineering Is Shaping the Future

The pace of innovation in 3D printing is staggering, and most of it traces back to better engineering. From automation to sustainability, the focus has shifted from “can it print?” to “how efficiently and intelligently can it print?”

Automation and AI

Today’s printers are getting smarter. Built-in AI can detect layer shifts, predict failures, and recalibrate automatically. Cameras and sensors feed data to algorithms that learn how to improve each print. Auto-calibration and real-time error correction are no longer luxury features — they’re expected.

All this intelligence takes the frustration out of printing. Instead of babysitting every job, creators can focus on design. Machines now handle the fine-tuning.

Industrial Applications

In manufacturing, 3D printing has outgrown the prototype stage. Aerospace companies produce titanium components with intricate internal structures. Automakers print lightweight brackets and test parts in hours, not weeks. Surgeons and dentists use patient scans to print implants that fit perfectly.

These examples prove how dependable the technology has become. Industrial engineering principles — precision, consistency, and repeatability — now guide every phase of 3D printing, from concept to production.

Sustainability

Sustainability isn’t just a bonus anymore; it’s a design requirement. Engineering has made 3D printing more efficient at every stage. Smarter software reduces failed prints, optimized part geometry cuts material use, and new eco-friendly filaments are being refined constantly.

Some printers use algorithms to minimize infill while preserving strength, saving up to half the material. Others recycle leftover filament into new spools. Engineers are proving that you don’t need to choose between innovation and responsibility — you can have both.

Rethinking What’s Possible

The evolution of 3D printing reflects the evolution of engineering itself: faster feedback loops, smarter tools, and a willingness to experiment. Makers are now building with industrial-grade precision, while big manufacturers are adopting the flexibility of small creators.

Advanced engineering has made 3D printing more accessible, more capable, and more creative. The real story isn’t just about better machines or tougher materials. It’s about how innovation and imagination are finally working side by side — turning ideas into reality at every scale.