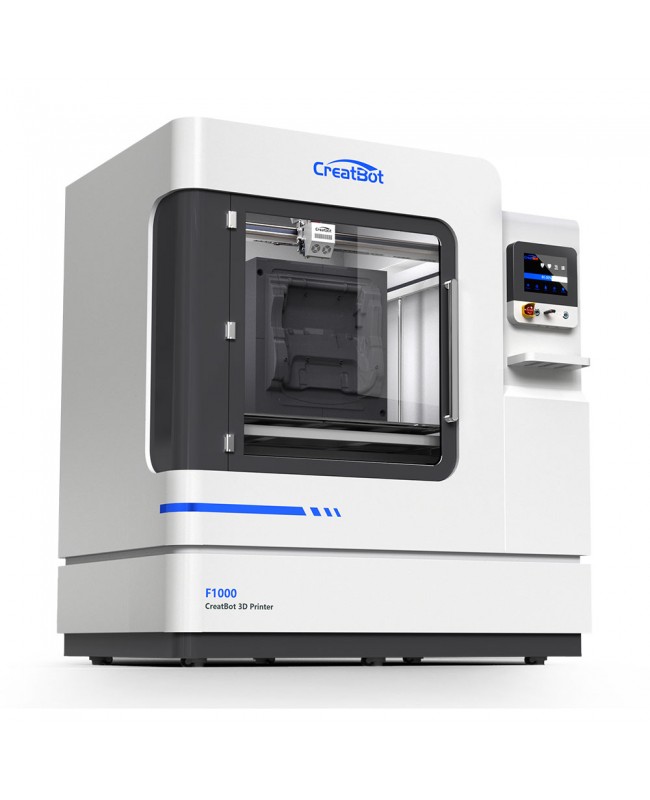

CreatBot F1000, Affordable and Reliable Large-Scale 3D Printer

"Better quality than German-made, much cheaper than Europe-price"

-- Roland Teo, CEO of Props factory Ltd.

F1000 has been upgraded to Creatbot D1000 HS.

CreatBot F1000 Highlights

- 420C Nozzle

- High Precision

- Metal Chassis

- Large BuildSize

- Outage Saving

- Filament Checking

- BuildTak Platform

- Touch Screen

- Linear Guide

- Precise Feeder

- Fully Enclosed

- Auto Leveling

- Hot Air Chamber

- Filaments Drying

- Camera Control

CreatBot F1000 was created to make industrial 3d printing of large-scale objects and prototype as easy as possible. It is an industrial 3d printer that responds to market demand and is embedded with a new smart dual extruder kit, an enclosed heated chamber, automatic leveling system and camera control for big, impressive, prints. Camera control technology allow customers to control printing process with an APP, which can get best printing quality with shortest time without failure. With a fast-heating platform and hot chamber this high-resolution large-print workhorse produces incredible results with high-quality materials. CreatBot F1000 sets a new standard in additive manufacturing and extends the material capabilities of large-scale 3d printers, it brings the possible to greatly reduce cost and time for more companies.

CreatBot F1000 will be your best choice with no doubt, if you are looking for an industrial large scale 3d printer for prototype and engineering-grade materials.

The most important, AFFORDABLE for every company!

| PRINTING SPECIFICATIONS | |

| Printing Technology | Fused Deposition Modeling |

|---|---|

| Build Volume | 1000*1000*1000 mm |

| Number of Extruders | Dual |

| Layer Resolution | 0.05mm |

| Print Speed | 60mm/s , Max 120 mm/s |

| Nozzle Diameter | 1.0 mm(0.4~1.5 mm) |

| Max Nozzle Temperature | 420C |

| Max. Heated bed temperature | 100C |

| Rated Power | 4000W |

| FILAMENT/MATERIAL SPECIFICATIONS | |

| Compatible with 3rd party materials? | Yes |

| Filament Diameter | 1.75mm |

| Material Type | ABS,PLA,Carbon Fiber,PETG,Nylon,PC,etc. |

| CONNECTIVITY(INTERFACE) | |

| SD Card Reader | Yes |

| USB Port | Yes |

| Display | 9.7-inch full color touch screen independent operating system (multi-language) |

| FEATURES | |

| Built in Camera for Monitoring | Yes |

| Filament runout detection | Yes |

| Levelling | Automatic leveling |

| Print Pause & Resume | Yes |

| SOFTWARE SPECIFICATIONS | |

| Supported Software/Slicing | CreatWare, Simplify 3D, Cura, Slice 3r, etc |

| Supported OS | Win7/8/10, MacOS |

| Supported File Formats | STL, OBJ, AMF, Gcode |

| ELECTRICAL SPECIFICATIONS | |

| Power Consumption | 220~240V, 50~60 Hz |

| DIMENSIONS & WEIGHT | |

| Product Dimensions | 1740*1300*1920 mm |

| Package Dimensions | 1910*1510*2205 mm |

| Product Weight | 550 Kg |

| Gross Weight | 640 kg |

+

+ +

+