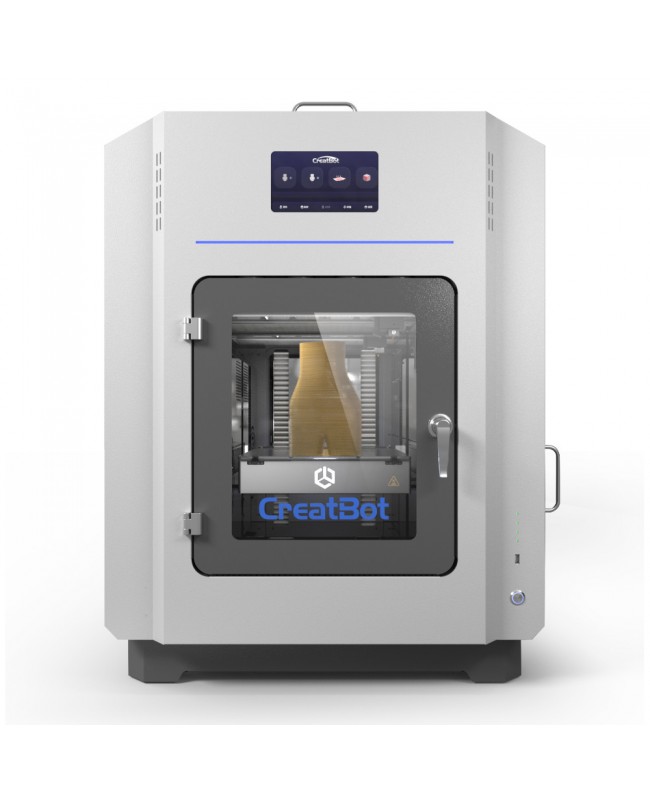

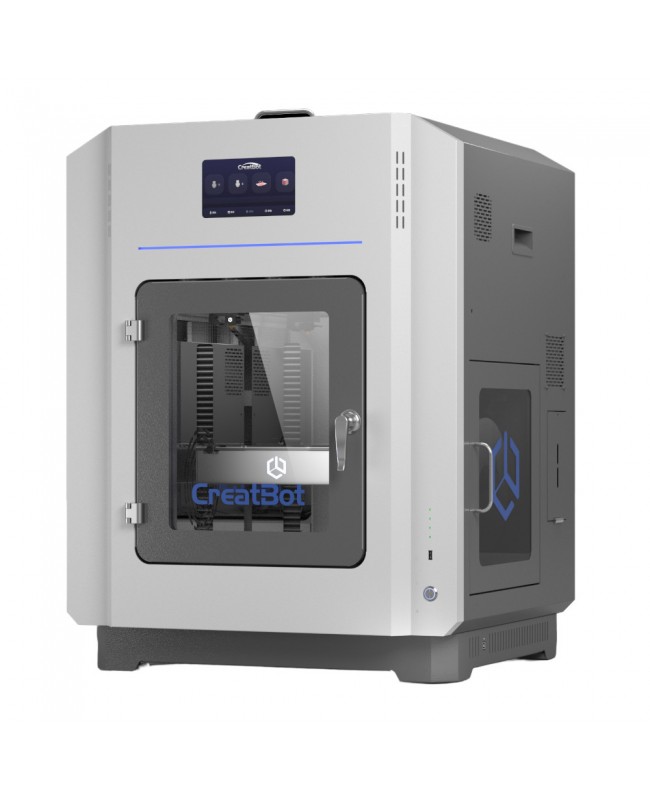

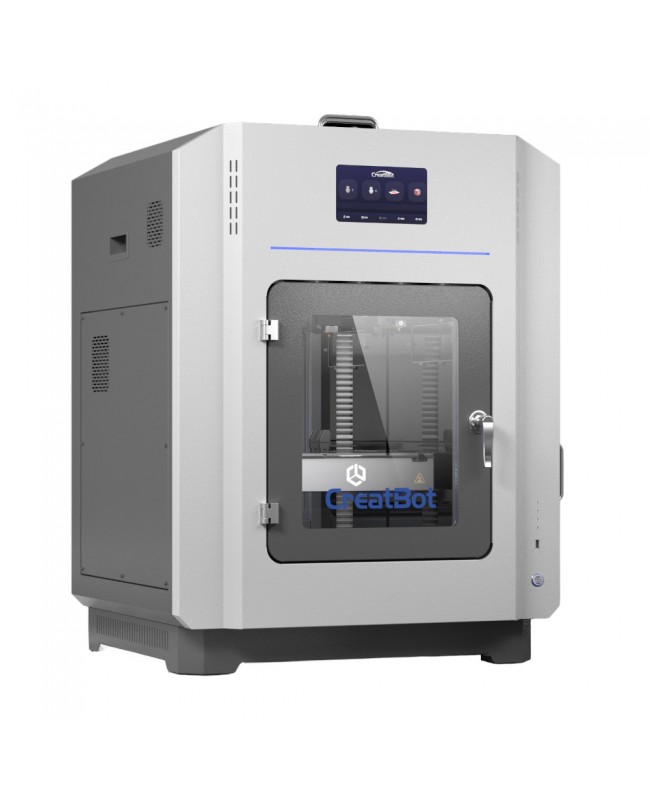

Creatbot PEEK-250 3D Printer

The Creatbot PEEK-250 stands out as the world’s first desktop 3D printer with a high-temperature chamber reaching up to 200°C. Its integrated direct annealing functionality, high-performance extruder system, and ultra-flat aerospace-grade build platform make it ideal for printing advanced polymers like PEEK and PEI with precision and ease.

Creatbot PEEK-250 3D Printer Key features & benefits

- Innovative High-Temperature Capabilities

- The chamber rapidly heats to 180°C within 20 minutes, ensuring optimal conditions for annealing advanced materials like PEEK.

- With integrated direct annealing functionality, models can be annealed directly within the printer, reducing deformation risks and eliminating the need for additional equipment.

- Pre-set annealing cycles allow precise temperature control, maintaining the environment for hours to ensure flawless results.

- A convenient one-click annealing feature simplifies post-processing. For instance, anneal PEEK parts at 180°C for 5 hours and 120°C for another 5 hours, all within the printer.

- Advanced Extruder System for High-Performance Materials

- Equipped with a double-tooth silicon carbide extruder, the PEEK-250 can handle filaments up to an impressive 500°C.

- This robust extruder is optimized for challenging materials, including carbon fiber and glass fiber composites, thanks to its high torque and wear resistance.

- An integrated cooling system ensures smooth, consistent performance even when printing demanding, high-temperature filaments.

- Aerospace-Grade Build Platform

- The PEEK-250 features an ultra-flat, polymer-coated build platform, delivering precision and reliability for every print.

- The platform’s 200°C high-temperature capability supports adhesion-free, warp-free printing.

- Eliminating the need for manual or automatic leveling, the design avoids sensor failures often associated with high-temperature environments.

- Overcoming High-Temperature Printing Challenges

- Many conventional printers are limited by the heat tolerance of components, but the Creatbot PEEK-250 overcomes these barriers with aviation-grade insulation and innovative cooling technologies.

- Its advanced engineering ensures the chamber’s high temperatures do not affect sensitive internal components, delivering reliable performance for high-performance polymers.

- User Safety and Thermal Insulation

- The thermally uniform 200°C chamber ensures consistent heating while prioritizing user safety.

- A specially designed spoiler promotes 360° circulation of hot air, enhancing material crystallization and uniform heating.

- Aviation-grade heat insulation keeps external surfaces, including the front and upper doors, touchscreen, and side panels, below 40°C, even during prolonged operation.

- Exceptional Print Quality

- A 200°C uniform heated chamber combined with an aerospace-grade platform ensures unparalleled precision.

- The result is warp-free, dimensionally accurate prints ideal for high-demand applications in industries such as aerospace, medical, and automotive.

Why should you choose the Creatbot PEEK-250?

- High-temp chamber (200°C) for advanced materials like PEEK and PEI

- One-click annealing eliminates complex post-processing challenges

- 500°C Silicon carbide extruder handles carbon fiber, glass fiber, and tough composites

- Aviation-grade insulation for safe and reliable long-term operation

- Ultra-flat aerospace platform guarantees precise, warp-free prints

- Streamlined, user-friendly design simplifies high-performance 3D printing

- Professional-grade engineering capabilities for cutting-edge innovations

Ideal Applications:

- Advanced Engineering Prototyping

- Aerospace Component Manufacturing

- Medical Device Development

- High-Performance Industrial Tooling

- Research and Laboratory Fabrication

Creatbot PEEK-250 Technical specifications

| Product | Creatbot PEEK-250 |

| Build Volume | 250*250*300 mm |

| Filament Diameter | 1.75mm |

| Number of Nozzles | Single Extruder |

| Nozzle Diameter | 0.4mm (0.3~1.0mm optional) |

| Filament Compatibility |

Engineering Plastics: PLA, ABS, ASA, PC, Nylon, PETG, PVDF,Carbon Fiber; High temperature Material: PET-CF, PET-GF, UltraPA, UltraPA-GF, UltraPA-CF, PPSU; Ultra-performance material: PEI(ULTEM™Full line), PEEK, PEEK-CF(Carbon fiber), PEEK-GF(glass fiber), PEKK, etc. |

| Best Printing speed | 55 mm/s |

| Max. Printing speed | 200 mm/s |

| Input Power | 200V~240V, 20A |

| Rated Power | 2500W |

| Screen | 7'' full color touch screen, multi-language |

| Print Method | USB Connectivity/USB Disk |

| Cooling | Air pump cooling & water cooling |

| Platform | PCB aluminum + PEEK print board |

| Positioning Precision | X Y axis 0.0127mm, Z axis 0.00125mm |

| Extruder | Directly Drive |

| Machine Construction | Fully enclosed hot chamber |

| Nozzle Max. Temperature | 480C |

| Chamber Temperature | 200C |

| Platform Max. Temperature | 200C |

| Software | Creatware, Simplify3D, Cura, Slic3r |

| Operating Systems | Windows, macOS |

| Print File Type | STL, OBJ, AMF, Gcode |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Thermal insulation | Three-layer insulation Active air cooling (Chamber temp. reaches 180 ° C, the external surface temp. is less than 40 ° C) |

| High temperature accessories | High temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing. |

| Doors cooling | Active air cooling |

| Machine Size | 630*555*815mm |

| N.W | 120 kg |

Buyer Protection Policies

| 100% Secure Payment | We accept PayPal, Credit, and Debit card payments (PCI DSS Compliant) |

| Insured Shipment | High-Quality Express Transport without damage |

| 1 Year Warranty | Just in case. Of course, we only ship out perfect products |

| Lifetime Support | Feel free to log the support ticket with us! |

Shipping Details

| Processing (Lead) Time | Ready to ship same or next business day! |

| Delivery Time to Doorstep (Transit) | Free Fast Shipping 3 to 5 days |

FAQ

Can the Creatbot PEEK-250 handle carbon fiber or glass fiber filaments?

Yes, the Creatbot PEEK-250 features a double-tooth silicon carbide extruder capable of reaching 500°C, designed specifically to handle challenging materials like carbon fiber and glass fiber composites. Its high torque and wear resistance ensure reliable and consistent performance.

How does the direct annealing function work on the Creatbot PEEK-250?

The direct annealing function allows you to anneal printed parts directly inside the printer. You can pre-set annealing cycles, specifying temperature and duration, for precise post-processing without removing the model. This reduces deformation risks and ensures stress-free, accurate results.

Is the Creatbot PEEK-250 safe for prolonged use?

Absolutely. The printer incorporates aviation-grade thermal insulation to keep external surfaces, like the front and upper doors and touchscreen, below 40°C even during extended operations. The thermally uniform 200°C chamber also ensures safety while delivering consistent print quality.

What materials can be printed with the Creatbot PEEK-250?

The Creatbot PEEK-250 is engineered to print high-performance polymers, including PEEK, PEI, and other advanced materials. Its high-temperature capabilities and robust extruder system make it suitable for demanding applications in industries like aerospace, medical, and automotive.

Does the Creatbot PEEK-250 require manual leveling of the build platform?

No, the Creatbot PEEK-250 eliminates the need for manual or automatic leveling. Its ultra-flat, polymer-coated build platform ensures reliable, warp-free printing without the complications of sensor failures in high-temperature environments.

+

+ +

+ +

+