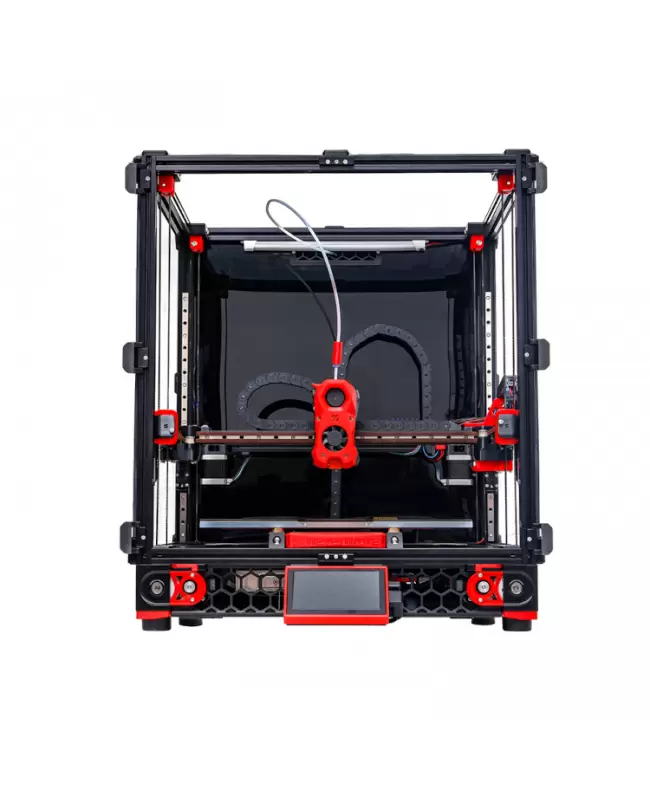

Voron 2.4 R2 Pro Plus (PRO+) CoreXY 3D Printer Kit

We're proud to partner with Formbot to bring their exceptional Voron kits to 3D printing enthusiasts in the USA and Europe.

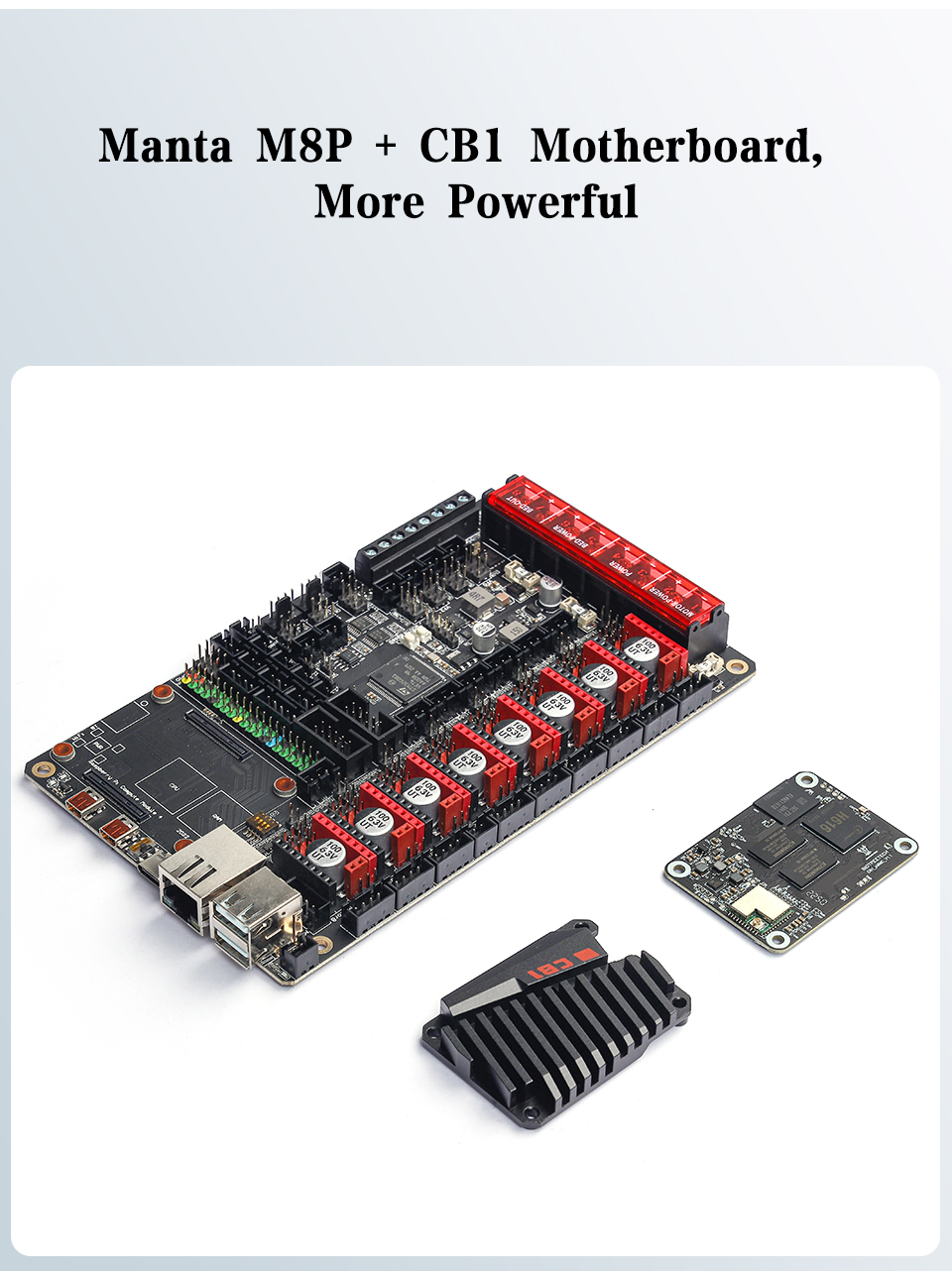

This latest version includes the BTT Manta M8P V2.0 board and an HDMI V1.2 touch screen, offering improved performance and a more user-friendly experience.

The Voron V2.4 by Voron Design is a well-engineered printer that looks promising. It has a great community that loves its builds and is well documented.

Voron 2.4 R2 PRO+ Key features

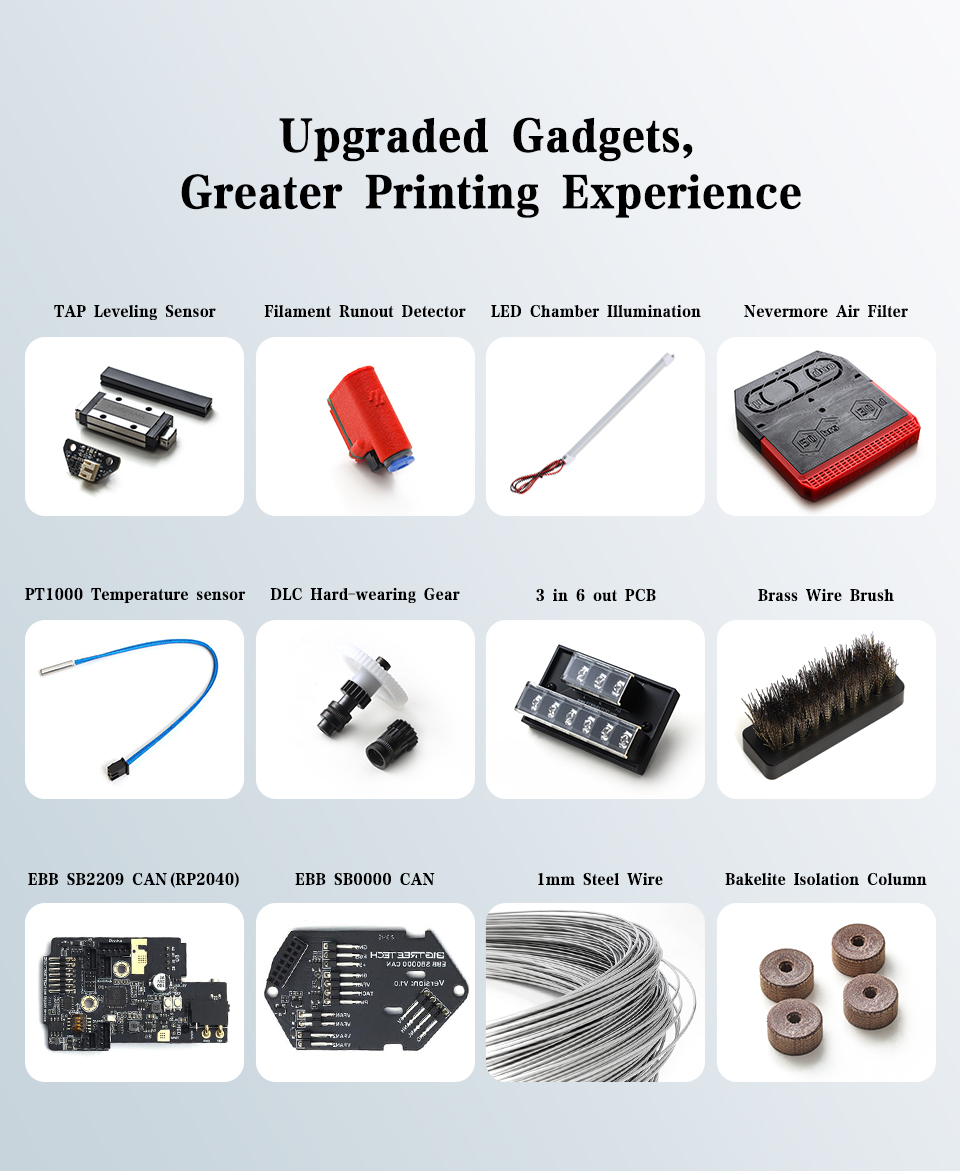

- Packed with the PRO+ features.

- HDMI 5“touch screen

- BTT Manta M8P + CB1

- EBB SB2209 CAN (RP2040) Stepper drivers.

- Tap sensor

- Toolhead PCB

- PVC cable duct

- filament runout sensor

- LED illumination inside chamber

- Nevermore air filter

- Input shaping ADXL345

- DLC hard-wearing gear

- End cap for DIN rails

- 3 in 6 out PCB for easier wiring

- Upgraded heating pad with integrated thermal fuse.

- Brass wire brush

- 1mm Steel wire

- Bakelite isolation column

- CNC Machined Tap leveling Kit (Optional upgrade)

- You can optionally upgrade to CNC TAP Leveling Sensor for improved accuracy. This upgrade can significantly enhance the precision of your prints

- Voron 2.4 R2 PRO+ Version w/ MGN12H rail for the x-axis and filtered power inlet.

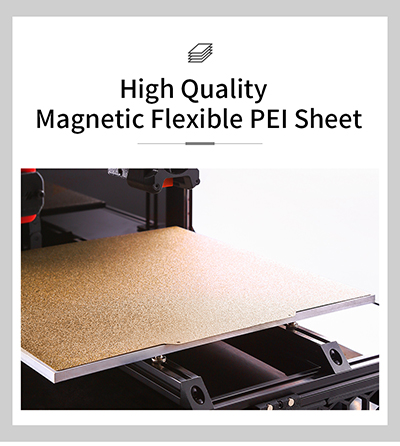

- Double sided PEI Sheet.

- BTT CB1.

- All-in-one kit (Hardware, Mechanical, Electronics, Frames, and All enclosed panels)

- Build volume: Scalable

- 250×250

- 300×300

- 350×350

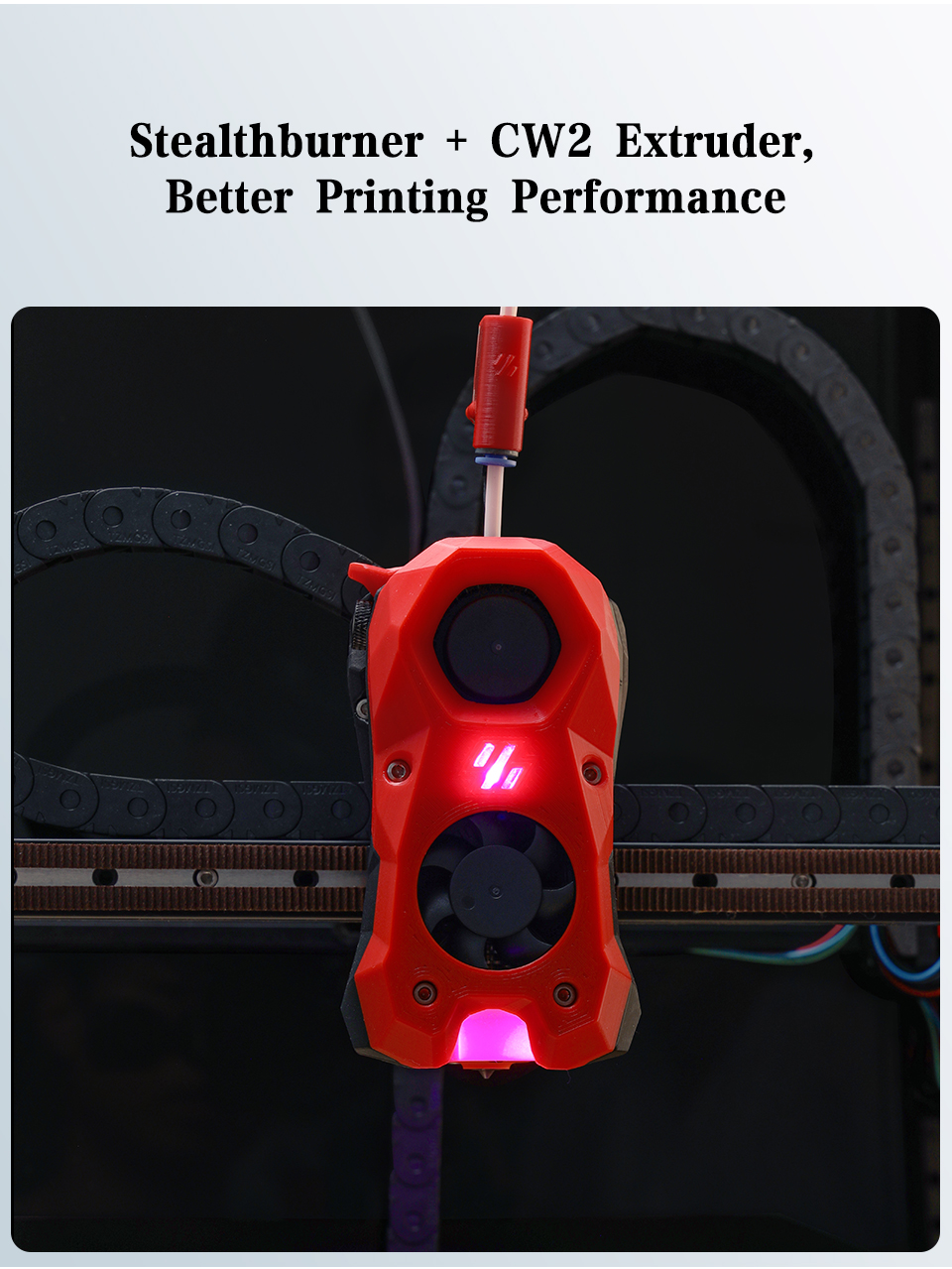

- Extruder: Stealthburner + CW2.

- Better Part cooling

- Better wire management. Easy to clean

- LED integration

- MIC6 Cast aluminum plate

- Pre-crimped Wiring harness

- Stainless steel fasteners

- Omron relay

- Moons' stepper motors

- Upgraded Version such as Moons' Motors, Pre Made Wiring harness, Omron Relay, and Cast aluminum plate are included

- Stock Open Source Voron V2.4 CoreXY design

- High Quality magnetic flexible PEI sheet

- Enclosure: High-Quality Fully Enclosed panels

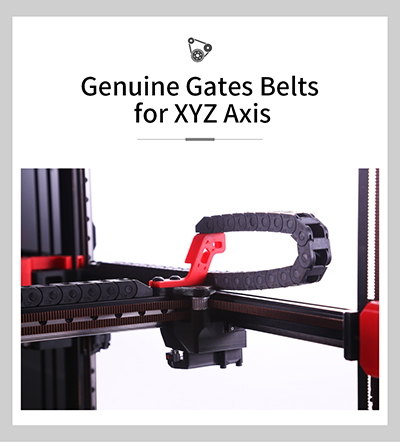

- Genuine gates belts for XYZ axis

- High-level stainless steel linear guide rails

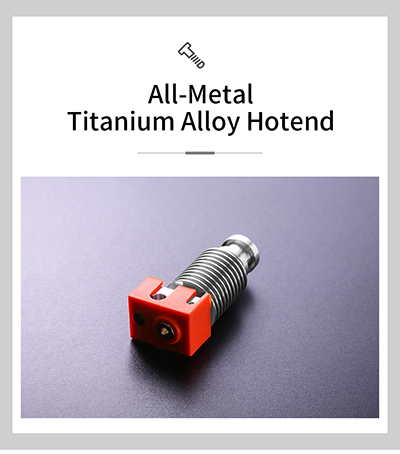

- By default, equipped with an all-metal titanium alloy V6 hotend

- Moving Gantry

- Electronics: BTT Manta M8P + CB1

- Voron Tap leveling sensor

- Extreme precision 0.4μm (0.0004mm)

- Any build surface and easily change at will

- Durability via optical sensor (millions of probe cycles)

- High temperature reliability (70C to 100C)

- Simplified probe mechanics (no dock/undock macros)

- No separate Z-endstop required

- Crash protection

- Optional Printed parts and BoxTurtle AFC kits are available

- The printed parts include functional parts and decorative ones; they are all printed in ABS+GF material, which is stronger and more heat resistant than normal ABS plastic.

- The current version of BoxTurtle AFC kit includes hardware parts for FilamATrix.

Advantages of BTT Manta M8P

Certainly! When comparing the BTT Manta M8P with the Octopus Pro, there are certain features and advantages that the Manta M8P may have:

- Integration: The Manta M8P is designed with a CB1/CM4 board-to-board connection, which provides a more streamlined and cleaner setup. This could be especially advantageous for those looking to reduce the wiring complexity and achieve a more integrated system.

- Voltage Selection for Fans: The Manta M8P offers an arsenal of fan ports that include voltage selection options between 5V, 12V, and 24V. This flexibility allows for greater compatibility with various fan specifications and can be particularly useful for users who may require different voltages for cooling or other purposes.

- Tachometer Support: Additionally, the M8P includes fan ports with tachometer support. The availability of such ports enables users to monitor the speed of their fans through firmware, an asset for precise thermal management within the printer.

- Customization: The M8P board, being part of the Manta series, is also known for allowing users a high degree of customization in terms of stepper drivers and other add-ons.

In summary, the BTT Manta M8P board offers an integrated and customizable solution for 3D printer builds or upgrades, with additional features for power and cooling management.

Advantages of BTT CB1

The BTT CB1 board presents several advantages over a general Raspberry Pi setup for Klipper, especially focusing on 3D printing applications. Here are some key points based on the information provided:

- Ease of Setup and Use: The BTT CB1 is reported to be straightforward to set up for Klipper, offering an ease of use that's particularly appealing for those in the 3D printing community. The provided images and access for the CB1 facilitate a smooth setup process.

- Tailored for 3D Printing: While both Raspberry Pi and BTT CB1 can run Klipper firmware, the BTT CB1 appears to have a design more specifically tailored towards 3D printing needs, potentially offering more optimized performance in such applications.

- Complementary Hardware: The BTT CB1's compatibility with other BTT hardware, such as the Manta series motherboards, allows for a more integrated and potentially more efficient 3D printing setup. This synergy could enhance overall performance and user convenience, with all hardware components designed to work seamlessly together.

- Community Feedback: Initial feedback from the community suggests that the BTT CB1 functions well as a substitute for Raspberry Pi in a Klipper setup, with users reporting positive experiences regarding its implementation and operation in a 3D printing context.

Given these points, the BTT CB1 board presents itself as a competitive option for those looking to run Klipper on their 3D printers, offering ease of use, tailored design for printing, and good community support, which are crucial factors for many users.

Note: We collect high-quality components for Voron V2 corexy 3d printer, so you don't need to buy anything from multiple stores as this saves your search time and cost for shipping parts separately. (Thanks for Voron Team's great work, they always design fantastic printers)

The Voron 2.4 is a lightweight and compact corexy motion system with a superior design. The printer has a moving gantry / fixed bed that utilizes four-point z-axis belts, which is unique for a corexy. The design is easily enclosed and has a lighter moving mass, setting it up for high-speed prints with beautiful parts. While the V2 is a great machine, it's probably not the best for first-time builders but does have a build guide that some say is far superior. Although the four Z-axis motors implementation and expansion board may be challenging for some, many more builds are much simpler to choose from that will produce great results. The Voron V2 has precision linear rails for the X- and Y-axes and a dual-drive extruder, making it a community favorite.

Voron 2.4 release re-focused on simplicity and cost for VORON2 and has been redesigned from the ground up to be more streamlined, more accessible to source, more fun to build, and generally a better machine to own. In short, what VORON used to stand for.

Voron 2.4 R2 PRO+ Technical specifications

| Model Number | Voron 2.4 R2 PRO+ Version |

|---|---|

| Max. Print Size | 250x250x250mm 300x300x300mm 350x350x350mm |

| Layer Height | 0.05~0.3mm |

| Nozzle Temp. | 300C |

| Bed Temp. | 110C |

| Nozzle Diameter | 0.4mm |

| Filament Diameter | 1.75mm |

| Max. Print Speed | 250mm/s |

| Max. Travel Speed | 300mm/s |

| Power Supply | 200W |

Documentation

STL

Guide

Wiring diagram

Motor Spec

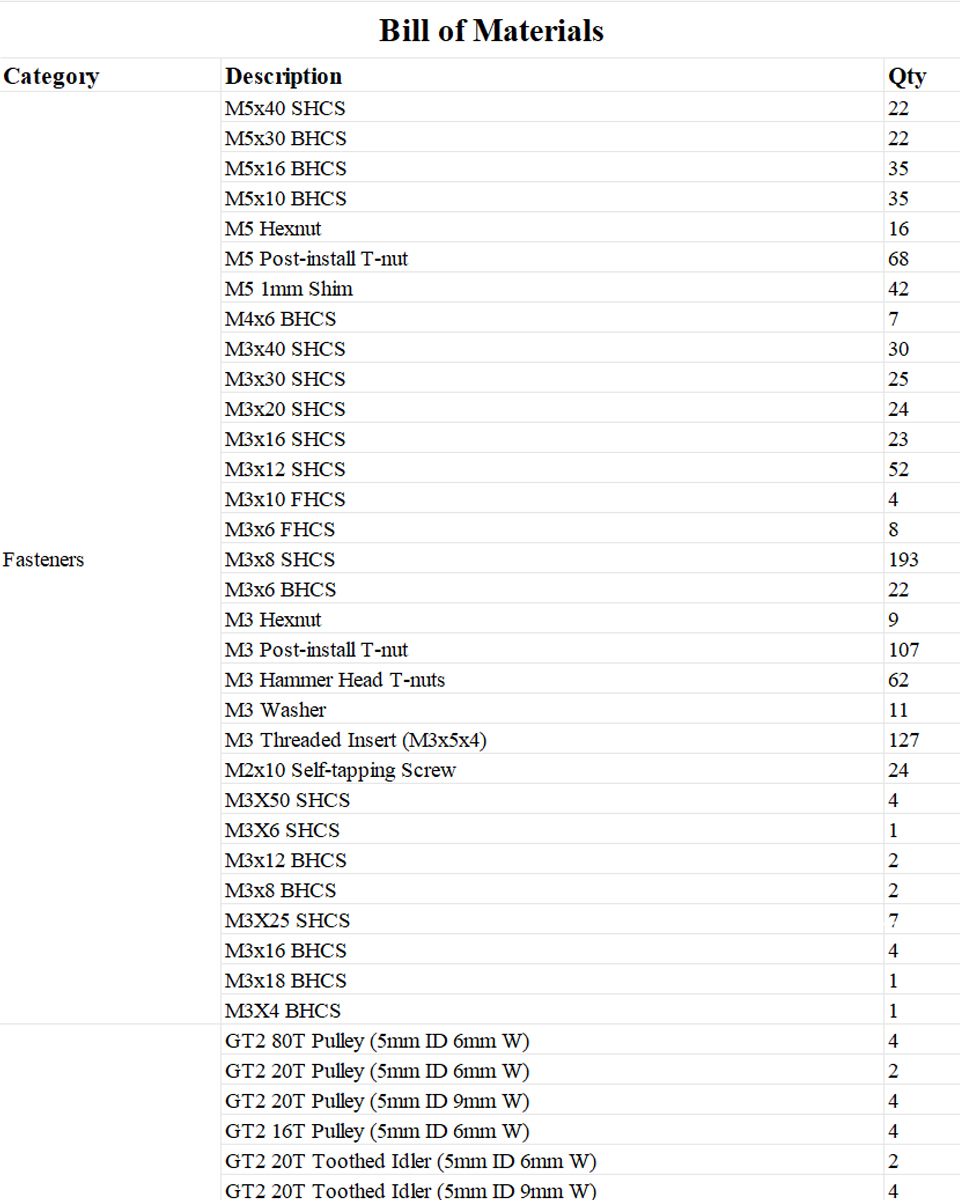

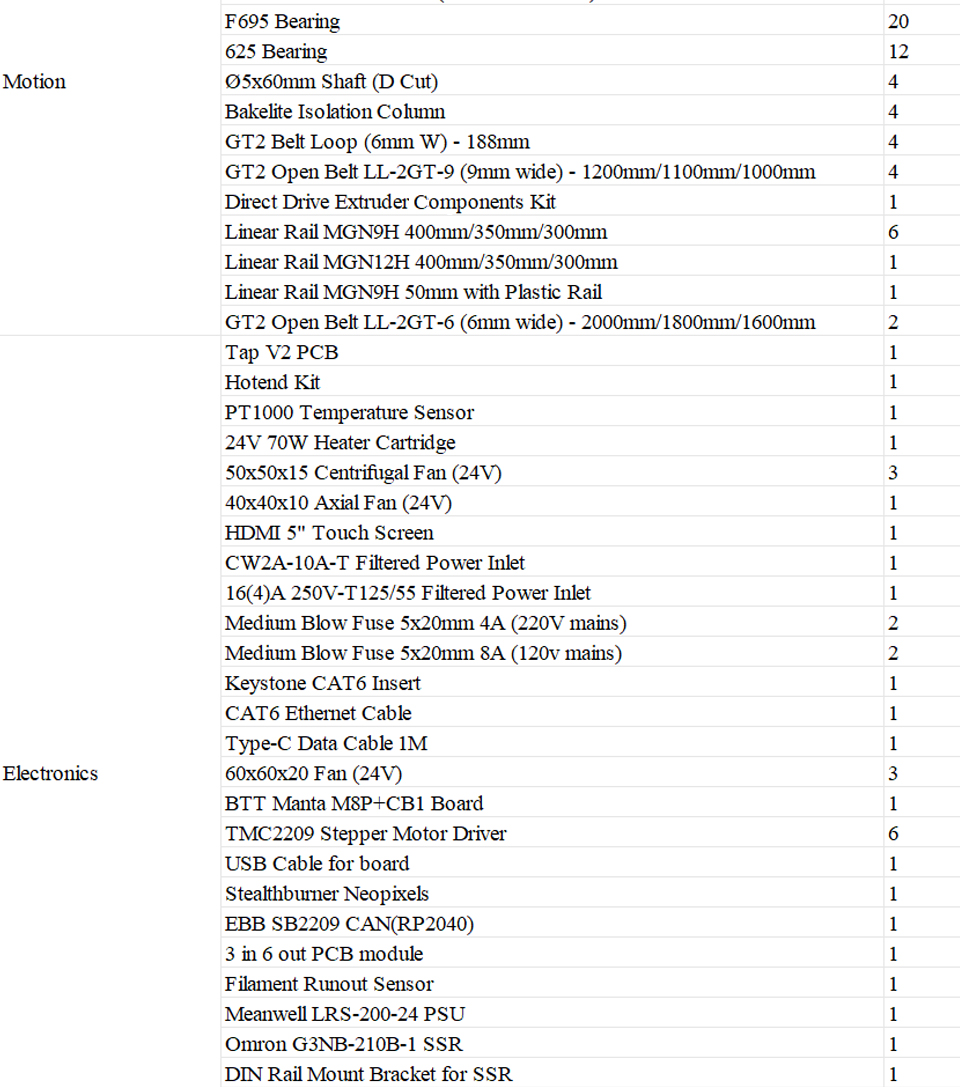

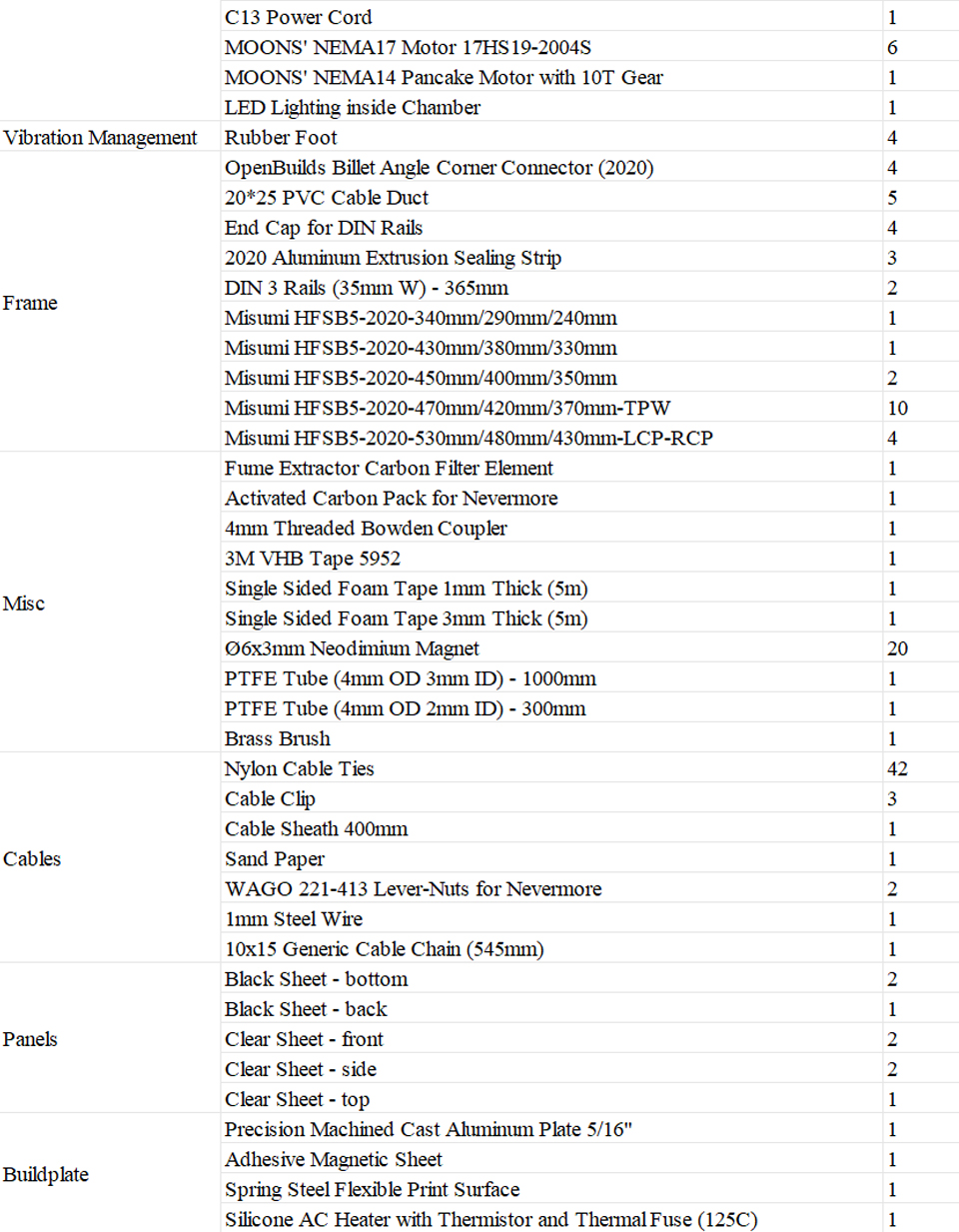

Voron 2.4 R2 PRO BOM(LATEST REV)

Voron 2.4 R2 Build guide

The following fixes & updates have been made since the previous release

- MGN12 X-Axis setup from Trident (originally member contributed)

- (note: as with Trident, the MGN12 setup drops compatibility with the PL series of inductive probes)

- Revised Z drive modules to fit guitar amplifier feet introduced with Trident. Maintains compatibility with compressor feet.

- Requires a modification to the bottom panel for upgrades from V2.4r1. Cut template included in the tools folder.

- New rear skirt layout relocating the power inlet and keystone pieces.

- Most unsupported countersunk bolt holes changed to using the cross-bridge method instead of a chamfer.

- Panel mount clips from Trident

- 1mm foam recommended for the top and rear panels

- 3mm foam for the side panels.

- Mini12864 display housing from Trident and updated for better compatibility with the BTT version of the screen.

- Simplified Z cable chain mounts using one screw and a printed retainer.

- Updated skirt fan mounts using M3 screws and heatsets to mount the fans and fan blanks. Inspiration for the heatset mounting method was taken from Ali Express vendor.

- Revised Z gantry blocks with extra material so the printed part touches the panels before the screw heads.

- Updated suggested electronics compartment layout to match Trident.

- Electronics DIN mounting clips from Trident.

- Updated exhaust filter housing with two screws holding the filter access cover.

- Added an exhaust filter fan grill to correct spacing for the fan mounting screws.

- Revised front idlers with tensioning screws moved to be in line with the idler pulleys. Inspiration for this modification was taken from a Github issue - posted by chrisingham05 (#255 ).

- Added mount for 3x5 WAGO 221 modules for inlet power wiring.

- Updated XY endstop pod compatible with both independent and PCB mounted D2F microswitches.

- Updated pulley jig for spacing assistance on all stepper pulleys and gears.

- Updated assembly manual to reflect the changes introduced by 2.4r2

| Buyer Protection Policies | |

| Safe & Secure Payments | We accept secure payments through PayPal, credit, and debit cards. Our payment processing is fully PCI DSS compliant, guaranteeing the highest standard of data protection for your transactions. |

|---|---|

| Insured Shipment | We ensure products are shipped out in perfect condition. |

| Warranty | 1 Year Manufacturer Warranty |

| Lifetime Technical Support | Need help? We’ve got your back—just raise a ticket, and we’ll take care of the rest! |

| Price Match Guarantee | We will match or beat any competitor's price. |

| Shipping information | |

| Lead time | 1 to 2 business days |

| Estimated Delivery time | Your order will arrive in 2 to 4 days via FedEx or UPS. |

+

+ +

+ +

+ +

+ +

+